I wasn’t planning to like Atomstack.

I’ve been in the laser engraving space for years, and I’ve tested everything—from overpriced all-in-one machines to cheap clones barely worth unpacking. Atomstack seemed to land somewhere in between: aggressive marketing, suspiciously high wattage claims, and surprisingly low prices. I expected mediocrity.

Instead, I found a machine that made me rethink what a $500–$1,000 laser engraver should deliver.

Here’s everything you need to know — the good, the bad, and the things no one tells you before you buy.

FIRST IMPRESSIONS: SUSPICION IS JUSTIFIED

Let’s start with expectations. If you’re coming from a branded experience like Glowforge or xTool, Atomstack feels stripped down. The interface is raw. The setup requires patience. And the documentation, while improving, still has that classic “translated from Chinese” tone.

The machines come disassembled. The instructions aren’t step-by-step in the modern sense. If you haven’t used LightBurn or LaserGRBL before, you’ll be Googling your way through your first session.

And then there’s the safety issue. Many Atomstack units, especially the open-frame models (A5 Pro, X7 Pro, X30 Pro), lack a built-in enclosure. You’re working with a high-powered diode laser, often with no case, no fume extraction, and no emergency shut-off switch unless you wire one in yourself.

These are not consumer-grade appliances. They’re tools. And like any proper tool, they demand responsibility and basic technical competence.

PERFORMANCE THAT SHUTS YOU UP

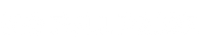

The turning point came around the third day of use. I had assembled the X30 Pro, added air assist, and fed it some 4mm birch plywood. The result: a clean cut in a single pass at 85% power and 300mm/min. I ran the same test on 3mm acrylic—cut clean with minimal edge melt.

The engraving quality also surprised me. I imported a grayscale image into LightBurn, adjusted the DPI, and ran it on bamboo. The detail was crisp, the gradient well-preserved, and no scorching. Once I understood how to focus properly and use air assist, the machine consistently delivered commercial-grade results.

Despite the low price, this wasn’t a hobby toy. It was clearly capable of serious output.

A BREAKDOWN OF REAL STRENGTHS

1. Power Efficiency and Throughput

Models like the Atomstack X30 Pro offer up to 33W of optical diode power. Now, real-world performance is always lower than the theoretical max, but the cutting power is real. You can process 8–10mm wood, 5mm acrylic, and even engrave some stainless steel (with spray or the right IR head).

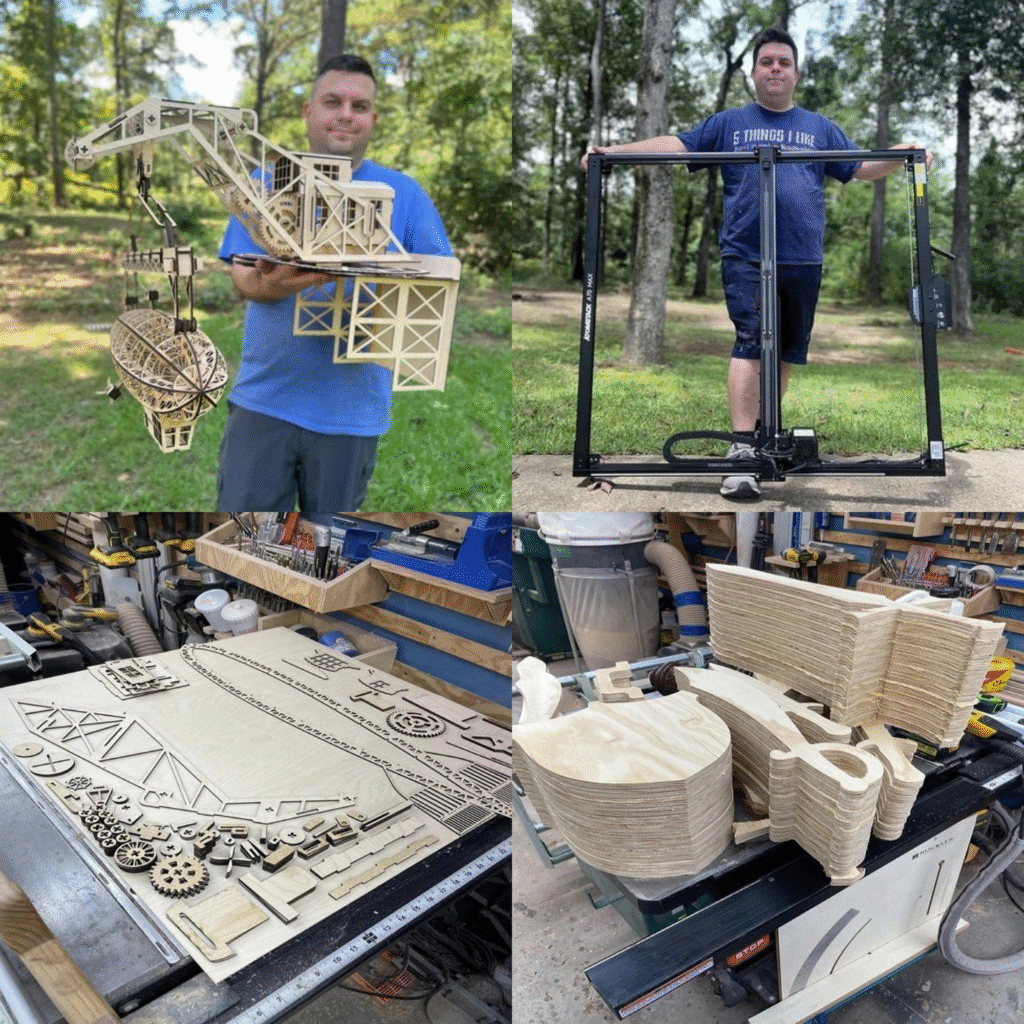

2. Mechanical Design

The frame is rigid and made from proper aluminum extrusions. Belts are tensioned correctly. The motion is smooth and precise. It doesn’t rattle or flex under pressure like some budget models do.

3. Modularity

You’re not locked into an ecosystem. You can upgrade with a rotary roller, camera system, honeycomb panel, air assist, or even swap in an IR laser for metal engraving. If you outgrow the base model, you’re not forced to start over—you just expand.

4. Software Freedom

Use what you like. LaserGRBL for basic tasks. LightBurn for serious control. No forced subscription. No artificial limitations. Just open architecture and flexibility.

WHO IT’S FOR (AND WHO IT’S NOT)

If you’re brand new to lasers, and you want something cute and enclosed that just works out of the box, Atomstack will frustrate you. It’s not built to walk you through every step or protect you from every mistake. It assumes you’re willing to learn, and to some extent, willing to fail before you succeed.

But if you’re:

- A woodworker, maker, or small business owner

- Comfortable with tools and software

- Looking to get serious cutting power without blowing $2,000+

- Willing to treat it like a machine, not a toy

Then Atomstack offers an incredible return on investment.

WHERE IT FALLS SHORT

Customer Support

It exists, but it’s not North American-standard. Response times are slow. Answers are basic. Most of the real help comes from YouTube channels, Facebook groups, and the LightBurn forums.

No Built-In Air Assist

You’ll need to buy an air pump separately (or as part of a kit). Cutting cleanly without it is difficult once you move past 3mm plywood.

Enclosure Costs Extra

Unlike some competitors, Atomstack doesn’t bundle in a safety enclosure. You’ll need to make one yourself or purchase an accessory.

Software Setup Curve

You’ll need to understand how to install drivers, calibrate offsets, and work in vector-based engraving software. It’s not rocket science, but it’s not beginner-proof either.

FINAL VERDICT: FROM DOUBT TO DEPENDENCE

I started with low expectations. I assumed I’d return it. I figured I’d be let down by support, hardware quality, or performance.

Instead, I now rely on this machine. I use it for product prototyping, gift engraving, and short-run production batches. It’s not just functional—it’s productive. And it’s not just a good deal—it’s a smart buy.

Atomstack is the kind of brand you hesitate to trust—until you use it. Then you wonder why you ever paid twice as much for half the performance.

It’s not for everyone. But for the right user, it’s the best decision you didn’t know you could make.